At Jones Heartz, we pride ourselves on our customer service, quality products, and timely project execution and management. Recently we realized that there was a problem with the way we managed our warehouse inventory- our production and orders were not cost-effective or time-effective. Because of this problem, we decided to switch to an electronic inventory system.

Although this system works now, its success did not happen overnight. Throughout the next few months, we will be introducing our new inventory system with a three-part blog series about how we identified the problem, implemented solutions, and our end results.

Our Biggest Issue

Before we transitioned to our Warehouse Management System (WMS), we relied on the expectation that our employees knew all our products and where they were so that we could pull them for our customers.

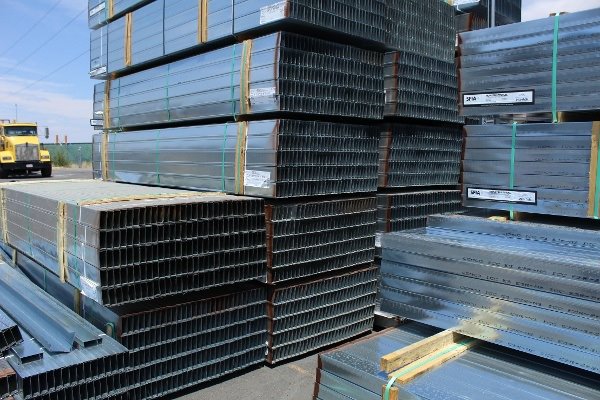

If you’ve ever been to Jones Heartz, you know that we have a large yard- sometimes finding a product can take up to 20 minutes. “When you have a will call customer waiting for 15 to 30 minutes for you to find the materials, it can become very frustrating for both them and the employee helping them,” says Patrick Duff, Warehouse Manager. “Mistakes tend to happen, and both parties quickly become unhappy.” When this issue began affecting our customer service, we knew that we had to make a change.

Importance of Knowing Your Inventory

When working in an industry that places a heavy importance on customer service, you have to know your inventory.

Knowing your inventory can show your customer that both you and your company know what you are selling and that you can meet your customer’s needs. “Having an accurate inventory allows you to give information out with confidence,” Patrick explained. “If our inventory is accurate, we can tell a customer with 100% confidence that we have the materials they’re asking for on hand. That’s a huge bonus for both our company and our customers when it comes to credibility and convenience.” This allows our customers to plan for their projects while letting Heartz know the number of materials we need to buy or not buy based on trends and inventory levels.

Our Thought Process for Change

When we reimagined a new warehouse system for Jones Heartz, we wanted to improve our inventory system and who the company was. “Innovation is a core value at Jones Heartz,” Patrick said. “We felt that this was a way to be innovative and grow while helping our company move in the right direction.” Using technology for our inventory process was an opportunity for Jones Heartz to improve our customer service and decrease our inventory costs, and that’s exactly what we did.

Want to See Our System in Action? Contact Us Today

Recognizing this problem has been a long but rewarding process for our company. Next month we look forward to explaining the challenges we faced while creating the system and how we transformed the way we handle our inventory today. Contact Jones Heartz today to see our warehouse inventory system in action and how we can help you with your project.